0

Need help?

Customer satisfaction is our priority. Whether you have questions about our sustainable containment solutions, need help with an order, or require assistance finding the right product for your needs, we’re here to help.

Customer satisfaction is our priority. Whether you have questions about our sustainable containment solutions, need help with an order, or require assistance finding the right product for your needs, we’re here to help.

Customer satisfaction is our priority. Whether you have questions about our sustainable containment solutions, need help with an order, or require assistance finding the right product for your needs, we’re here to help.

Whether you’re transporting a pole-mounted transformer, managing PCB hazards, or conducting transformer spill containment during field maintenance, having the right containment bags in place protects the environment, ensures regulatory compliance, and streamlines workflow.

At ABG Bag Inc., we understand the unique challenges utility companies, environmental service providers, and infrastructure contractors face when handling oil-filled or PCB-containing transformers. That’s why we’ve developed this essential guide to transformer containment and transport bags—to help you make informed, safe, and compliant decisions.

Below, we’ll explore the critical aspects of containment bag selection, highlight the importance of DOT-approved solutions for transport, and outline how specialized containment options help prevent environmental risk from utility poles and PCB transformers.

Transformer containment bags are specifically engineered to contain spills, leaks, or residues from pole-mounted, pad-mounted, or industrial transformers. These bags act as an essential barrier between hazardous transformer fluids and the surrounding environment, particularly in outdoor, high-risk, or remote utility locations.

Made from high-strength, chemical-resistant materials, containment bags are designed to:

Whether the transformer is being transported, removed, inspected, or temporarily stored, having a reliable transformer oil containment bag in use is crucial to maintain both compliance and control over environmental risks.

Transformer spills—whether from cracked housings, damaged bushings, or accidental drops—can result in serious oil contamination, costly cleanup operations, and significant environmental liabilities. These spills are not only hazardous to personnel but can also seep into soil, waterways, and storm drains, leading to long-term ecological damage. Having the correct transformer containment bag on-site dramatically reduces the risk and consequences of such incidents.

Selecting the appropriate containment solution is more than a matter of convenience—it’s a matter of safety, compliance, and environmental stewardship.

Not all containment bags are created equal. The effectiveness of a bag depends heavily on its construction, materials, size, and handling features. When evaluating options, especially for field or transport use, consider these essential features:

Transformer oils and related fluids can break down inferior materials, causing leaks and bag failure. Choose multi-layer reinforced containment bags made from industrial-grade materials that are resistant to:

For outdoor utility work, a UV-resistant coating helps preserve bag integrity under prolonged sun exposure, ensuring the bag remains strong during long periods of deployment or transport.

Effective containment depends on a completely sealed system. Look for:

These features greatly reduce the chance of a leak during movement, transfer, or long-term storage.

Transformers vary significantly in weight—some smaller pole-mount transformers may weigh under 200 lbs, while larger industrial or pad-mount transformers can exceed 2,000 lbs. Ensure the transformer containment bag is properly rated to handle the intended load. A mismatch between weight and bag capacity increases the risk of rupture during lifting or transport.

The size of the transformer bag must match the transformer’s dimensions for effective containment and safe handling. Bags that are too small may not close securely, while oversized bags may shift during lifting. Look for containment options in a variety of sizes:

Having the right size reduces handling risks and ensures full coverage during spills or transportation.

Transformer transport often requires cranes, hoists, or forklifts. Transformer transport bags should be equipped with:

These features allow safe and secure handling when moving heavy equipment and ensure compliance with OSHA and DOT handling guidelines.

Containment bags should be part of your standard operating equipment anytime a transformer is being handled outside its permanent installation.

A containment bag should be deployed immediately if a transformer begins leaking in the field. Bags act as a rapid-response containment system that protects the surrounding area while the unit is stabilized or removed.

During infrastructure upgrades or replacements, transformers being removed may still contain residual oils. Pole mount transformer containment bags allow safe removal without the risk of spilling hazardous fluid onto roads, sidewalks, or vegetation.

Containment bags also serve as temporary storage units during lab testing or safety inspections, offering a secure holding environment and preventing environmental exposure.

Natural disasters and vehicular accidents can knock down power poles, damaging transformers in the process. Having utility pole containment bags ready to deploy can help first responders and utility crews contain spills until proper removal is arranged.

Planned maintenance often includes draining transformers for repairs or transport. Bags provide secure containment of any leftover fluids and prevent drips or leaks during handling.

Investing in proper transformer containment not only reduces environmental risk, but it also:

Simply put, safety starts with preparation. Keeping high-quality transformer containment bags on-site, in service vehicles, and in staging kits ensures your team is ready to act quickly and responsibly—protecting both people and the planet.

Transporting transformers—particularly those that are oil-filled or contain polychlorinated biphenyls (PCBs)—is not a task to take lightly. The movement of these units involves the handling of hazardous materials and is governed by strict regulations. To avoid costly violations and environmental risk, it’s essential to use DOT-approved containment bags that meet all requirements established by the U.S. Department of Transportation (DOT).

These specially engineered bags are a critical component of any transformer logistics or response strategy. They ensure not only the safety of handlers and the environment but also the legal compliance of every shipment.

The DOT has established comprehensive standards for the transportation of hazardous materials to ensure public safety and environmental protection. When it comes to transformers, DOT regulations apply to any unit that contains, or may contain, substances such as:

Failure to properly package and label these transformers can result in serious consequences, including:

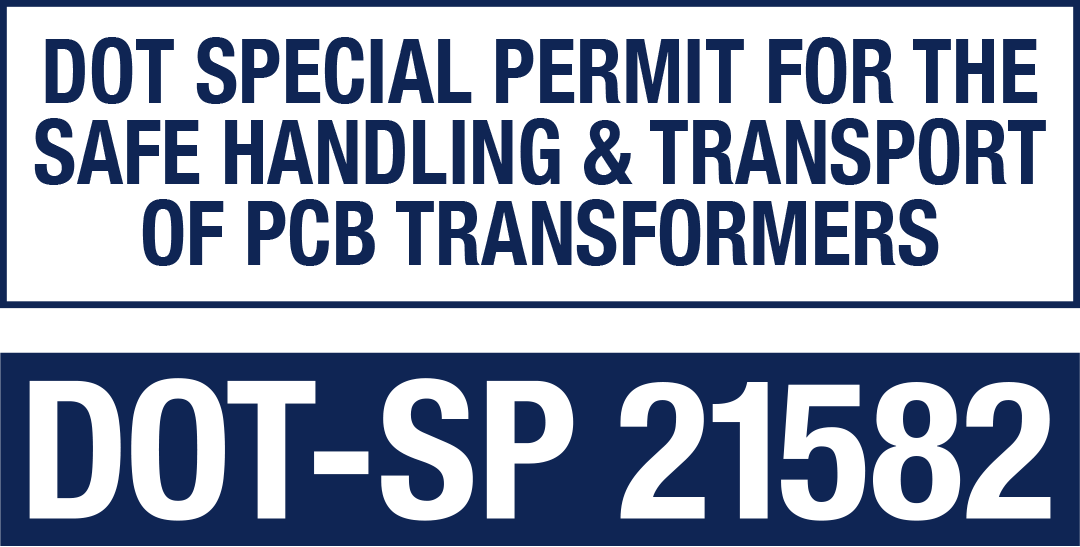

Using DOT-approved containment bags ensures that your company or crew is compliant with federal law while minimizing the likelihood of spills, exposure, or fines during transport.

DOT’s hazardous materials regulations (HMR), outlined in Title 49 of the Code of Federal Regulations (CFR), require that hazardous shipments be:

DOT-approved transformer containment bags are designed to meet or exceed these packaging and handling requirements. They provide a safe, reliable solution for both routine transport and emergency incident response.

When choosing a transformer transport bag or PCB transformer containment bag for regulated shipment, look for the following features to ensure full DOT compliance and dependable performance:

DOT-approved containment bags are manufactured with multi-layer leakproof materials that offer maximum protection against spills. These materials are resistant to:

Sealed seams, interior liners, and reinforced corners help prevent leakage and maintain containment integrity—even under long-distance transport conditions.

Compliance isn't just about physical protection—it also involves clear communication. DOT requires hazardous materials to be marked and labeled correctly. The best containment bags offer surfaces or attachment areas for:

Some bags come with built-in sleeves or label pockets for easier document management and tracking throughout the shipping process.

Safe lifting and transport is essential when dealing with transformers that may weigh hundreds or thousands of pounds. DOT-compliant containment bags should be:

These features not only ensure compliance but also protect handlers from injury and reduce the risk of equipment damage during loading or unloading.

Reputable DOT-approved bags are tested and certified to meet packaging and durability standards outlined in 49 CFR. Bags should be tested for:

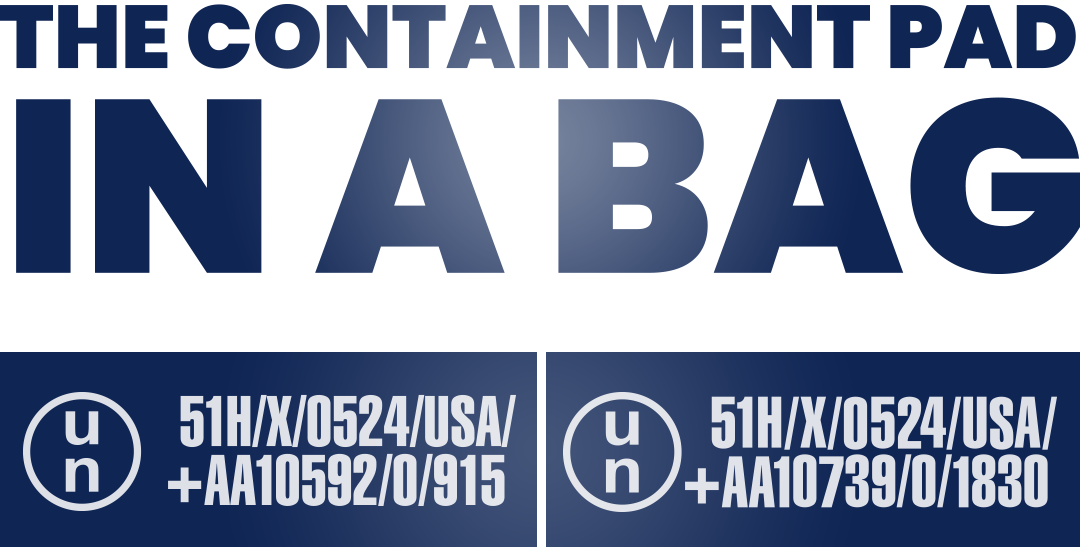

Some containment bags may also be rated under UN packaging codes for the transportation of specific hazardous classes, offering additional regulatory coverage and peace of mind.

DOT-compliant containment solutions are required in a variety of operational contexts. Utility companies, remediation contractors, and environmental service providers often encounter scenarios where these bags are essential:

Older transformers may contain residues of hazardous materials. Before shipping to reclamation or recycling facilities, units must be fully enclosed in DOT-approved transformer containment bags to prevent leakage during transit.

When relocating active or retired transformers between job sites, substation yards, or storage facilities, containment bags ensure that any residual oil or sludge remains safely enclosed—especially in the event of damage during movement.

PCB transformer containment bags provide the necessary containment for regulated transport of equipment that contains, or is suspected to contain, polychlorinated biphenyls. This is especially important when removing transformers for disposal under EPA guidelines.

After accidents, natural disasters, or transformer malfunctions, rapid removal may be necessary. DOT-approved bags allow emergency crews to contain leaking units and transport them safely and legally—minimizing environmental impact and exposure risk.

Using a containment bag that is not DOT-approved may seem like a cost-saving shortcut, but it introduces serious risk. Non-compliant packaging can lead to:

Choosing a DOT-approved containment bag is the only way to guarantee regulatory compliance and maintain control over hazardous transformer movement.

Whether you’re working on large-scale infrastructure upgrades, decommissioning legacy equipment, or responding to environmental emergencies, DOT-approved containment bags are a non-negotiable part of your toolkit. Their use demonstrates a commitment to safety, compliance, and environmental responsibility.

By choosing certified, transport-friendly containment solutions, you protect your people, the public, and your projects—while staying firmly within the law.

While general containment and transport solutions are vital for everyday transformer handling, certain applications demand even more specialized containment systems. In particular, utility pole containment bags and PCB transformer containment bags are designed to manage highly specific environmental and regulatory risks that arise from aging infrastructure, storm damage, or the handling of hazardous legacy equipment.

Both types of containment solutions serve critical roles in environmental protection, public safety, and regulatory compliance, helping utilities and service crews prevent contamination in the field and remain compliant with both state and federal environmental guidelines.

Pole-mounted transformers are widespread throughout utility networks and can be found in urban neighborhoods, rural corridors, and industrial areas alike. Due to their elevated position and constant exposure to environmental elements, these transformers are vulnerable to:

When these events occur, transformer oil and other fluids can leak rapidly, falling directly onto the ground below. Without fast and effective containment, these leaks can contaminate soil, run into stormwater systems, or spread to sensitive ecosystems.

Specialized utility pole containment bags are designed specifically for these high-risk scenarios. Unlike general containment products, these bags offer features that make them particularly effective in the vertical, elevated environments typical of pole-mounted equipment.

Time is of the essence in environmental protection. These containment bags can be deployed quickly and easily by field technicians in emergency situations. Some models can be wrapped directly around the transformer or fastened at the base of the pole within minutes, offering immediate containment.

Because pole-mounted transformers are suspended above ground, pole mount transformer containment bags are engineered for vertical and elevated positioning. Custom-fit designs help the bags stay securely in place, even in windy or unstable conditions. Some feature closures or fasteners that allow them to wrap snugly around the body of the transformer, acting as a protective sleeve in the event of a spill.

To increase effectiveness, many pole-mount containment bags include absorbent liners or pads built into the interior. These liners soak up transformer oil as soon as it leaks, minimizing spread and reducing the risk of drips during transport or removal. In many cases, absorbent materials are treated to resist chemical degradation and remain effective over time.

One of the most important benefits of utility pole containment solutions is their ability to prevent oil from seeping into the soil or stormwater. This is especially critical in residential areas, parks, or near wetlands, where even a small leak can lead to environmental violations or require costly remediation.

Transformers may be static equipment, but the risks they carry are dynamic—especially when age, weather, or impact causes unexpected leaks or failures. The proper deployment of utility pole containment bags and PCB transformer containment bags ensures your crew can respond quickly and responsibly to protect both people and the environment.

These tools are not optional—they are essential components of a complete containment and compliance strategy.

To get the most value and protection from your transformer containment bags, implement the following best practices:

Before use, inspect all bags for punctures, seam defects, or signs of wear. Always have backup units on hand.

Ensure all staff who handle transformers understand how to properly deploy, secure, and transport containment bags. Include hazmat and environmental procedures in training programs.

Keep containment bags stored in easily accessible, clearly marked kits for fast deployment in emergency or maintenance situations.

Use containment as part of your environmental response documentation. Note bag use, containment success, and transport method for internal or regulatory records.

After use, follow proper disposal or cleaning guidelines, especially when handling PCB-containing equipment.

Organizations across the utility, telecom, rail, and power generation sectors rely on transformer containment bags to reduce risk and ensure readiness. Common use cases include:

When environmental compliance, worker safety, and operational efficiency are on the line, choosing high-quality transformer spill containment solutions is non-negotiable. Inferior products may cost less upfront but pose serious long-term risks, including:

ABG Bag Inc. provides solutions engineered for reliability in the toughest environments. Every containment bag we offer is designed with safety, compliance, and performance in mind.

We supply a full range of containment solutions, including:

Whether you’re maintaining a substation or responding to an emergency in the field, we have the right containment solution for your team.

For inquiries about our products, order status, or any other information related to ABG, send us a message, and we will respond soon.

Sales & Customer Care

Product Questions

Adding {{itemName}} to cart

Added {{itemName}} to cart