0

Need help?

Customer satisfaction is our priority. Whether you have questions about our sustainable containment solutions, need help with an order, or require assistance finding the right product for your needs, we’re here to help.

Customer satisfaction is our priority. Whether you have questions about our sustainable containment solutions, need help with an order, or require assistance finding the right product for your needs, we’re here to help.

Customer satisfaction is our priority. Whether you have questions about our sustainable containment solutions, need help with an order, or require assistance finding the right product for your needs, we’re here to help.

Transformers are essential components of the electrical grid, quietly ensuring that electricity is delivered safely and efficiently from power plants to homes, businesses, and public infrastructure. While many people recognize the familiar cylinder mounted on a pole, transformer systems come in several forms, each designed for specific voltage levels, environments, and usage demands. Understanding the types of residential and utility transformers helps clarify how electricity is distributed and why proper handling, transport, and installation are so important.

At ABG Bag, we support organizations that work with transformer equipment throughout its lifecycle, from staging and transport to installation and replacement. This guide explores the most common transformer types used in residential and utility settings, explains how they differ, and outlines their real-world applications.

In most residential neighborhoods, electricity is delivered through a residential electric transformer mounted on a utility or telephone pole. This transformer is a key part of the local distribution network and serves as the final step in reducing voltage before power enters homes. Electricity arrives in neighborhoods at distribution-level voltages that are far too high for household use, and the transformer’s role is to convert that energy into a form that is safe, stable, and compatible with residential electrical systems.

A power pole transformer, also commonly called a telephone pole transformer or polemount transformer, is typically designed as a step-down transformer. It receives electricity from overhead distribution lines that may carry several thousand volts and reduces that voltage to standard household service levels, most commonly 120/240 volts. This conversion allows electricity to power everyday needs such as lighting, appliances, heating and cooling systems, and electronic devices without damaging equipment or wiring.

Residential transformers are engineered to support the specific load demands of the areas they serve. In suburban neighborhoods, a single electric transformer on pole may supply power to multiple nearby homes, balancing demand across several service connections. In rural areas, where homes are spaced farther apart, a transformer may serve only one or two properties but must be capable of maintaining voltage stability over longer distances. In both cases, the transformer must operate reliably under varying load conditions throughout the day and year.

Several key characteristics define residential transformers and make them suitable for neighborhood installations:

These features allow residential transformers to function reliably for many years, often decades, with little intervention beyond routine inspection. Because these units are installed close to homes and businesses, safety is a top priority. Electrical isolation between high-voltage and low-voltage circuits helps protect people, property, and connected equipment.

Proper installation is essential to transformer performance. Utilities carefully select mounting height, grounding methods, and placement to ensure clearance from structures and safe access for maintenance crews. Routine inspections help identify wear, corrosion, or other issues before they affect service reliability.

Careful handling during transport is also a critical factor in long-term performance. Damage sustained while moving a transformer to a job site may not be immediately visible but can compromise internal components and shorten service life. Using appropriate lifting, securing, and protective measures during transport helps preserve transformer integrity from the start.

Overall, the residential electric transformer plays a vital role in delivering dependable power to homes. Its design, placement, and maintenance directly influence the safety, reliability, and quality of electrical service experienced by end users every day.

Transformers can be classified in many different ways, including by size, voltage rating, cooling method, or installation environment. One of the most common and practical ways to group them, however, is by function and application within the electrical system. While there are many specialized designs, four broad types of transformers are most commonly referenced across residential, commercial, and utility power networks. Each type plays a specific role in moving electricity safely and efficiently from generation to end use.

Step-up transformers are designed to increase voltage levels. These transformers are typically located near power generation facilities, where electricity is produced at relatively low voltages. To make long-distance transmission efficient, the voltage must be increased before electricity enters high-voltage transmission lines.

Raising the voltage significantly reduces energy loss as electricity travels over long distances. This makes step-up transformers essential for regional and national power grids. Because they handle extremely high voltages and large power capacities, step-up transformers are usually large, heavy units installed in substations rather than mounted on poles.

Although step-up transformers are not seen in residential areas, they are a foundational part of the overall system that allows electricity to reach homes and businesses reliably. Without them, long-distance transmission would be inefficient and impractical.

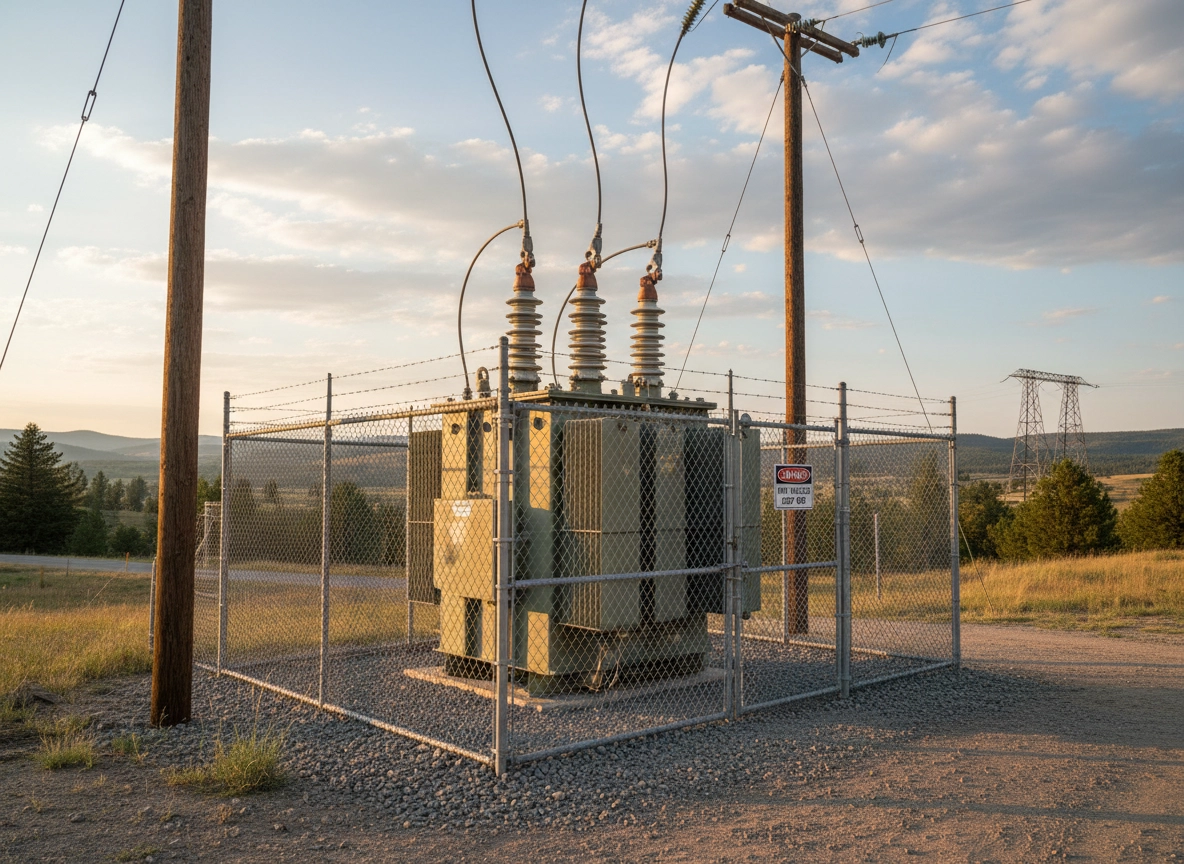

Step-down transformers perform the opposite function by reducing voltage levels. These are the most familiar type of transformer to end users and are widely used throughout utility distribution systems. A power transformer on pole is a classic example of a step-down transformer, lowering distribution voltage to levels suitable for residential and light commercial use.

Step-down transformers are found at multiple points in the grid. Large units at substations reduce transmission voltage to distribution levels, while smaller units, such as pole-mounted transformers, perform the final voltage reduction before power enters buildings. A utility transformer installed in a neighborhood ensures that electricity arrives at a safe, usable voltage.

Because step-down transformers operate close to end users, they are designed for continuous operation, reliability, and safety. They must handle changing electrical loads throughout the day without overheating or losing efficiency.

Isolation transformers transfer electrical energy from one circuit to another without changing the voltage. Their primary purpose is electrical isolation rather than voltage conversion. By separating the input and output circuits, isolation transformers help protect equipment and users from electrical faults, surges, and interference.

These transformers are commonly used in environments where safety and power quality are critical, such as medical facilities, laboratories, and industrial settings with sensitive equipment. Isolation transformers also help reduce electrical noise, which can interfere with precision electronics.

While isolation transformers are less common in residential distribution systems, they play an important role in specialized commercial and industrial applications. Their ability to improve safety and signal quality makes them a valuable part of certain electrical designs.

Distribution transformers represent a broad category that includes most transformers used to deliver electricity directly to end users. This category encompasses both pole-mounted and pad-mounted units and is central to everyday power delivery.

A utility transformer used in a residential area is a type of distribution transformer. These units are designed to operate continuously, often for decades, while exposed to outdoor conditions and varying electrical loads. Distribution transformers must balance efficiency, durability, and safety to ensure consistent service.

Pole-mounted distribution transformers are common in areas with overhead power lines, while pad-mounted transformers are often used in neighborhoods with underground distribution systems. Regardless of configuration, distribution transformers serve as the final link between the utility grid and the customer.

Each of these four transformer types serves a distinct purpose within the electrical grid. Step-up transformers make long-distance transmission possible, step-down transformers adapt power for safe use, isolation transformers protect equipment and improve power quality, and distribution transformers deliver electricity directly to end users. Together, they form an interconnected system that supports efficient, reliable, and safe power delivery from generation to consumption.

Utility transformers are critical components in the electrical infrastructure, owned and operated by electric utilities or other infrastructure providers. Their primary purpose is to facilitate the transmission and distribution of electricity over wide service areas, ensuring that power generated at plants can reach homes, businesses, and industrial facilities safely and efficiently. Without utility transformers, the electricity generated at high voltages could not be reduced to levels suitable for end-use, making them indispensable to modern power systems.

An electric utility transformer may be installed in a variety of configurations depending on the location and purpose. Some are pole-mounted transformers, commonly seen in residential neighborhoods, where they reduce distribution voltage to household levels. Others are pad-mounted transformers, placed at ground level in areas with underground electrical distribution networks. Large substation transformers handle high-voltage transmission and distribution, stepping down power to levels suitable for local distribution lines. Regardless of placement, every utility transformer is engineered for durability, efficiency, and long-term performance.

One defining characteristic of utility transformers is their ability to operate continuously. These units are designed to handle 24/7 operation for decades, often under challenging conditions such as extreme weather, fluctuating electrical loads, and environmental stress. Because of this, utility transformers incorporate high-quality insulation, robust cores, and protective enclosures to ensure consistent performance and minimize the risk of failure.

Modern new utility transformers are designed with improved materials and engineering techniques to meet today’s efficiency standards and environmental regulations. Compared to older models, these newer units offer reduced energy losses, quieter operation, and enhanced longevity. Advances in design also make them more resistant to overheating and mechanical stress, which helps maintain stable voltage delivery across the grid.

Utility transformers come in several common types, each suited to a specific role within the distribution and transmission network:

Together, these types of utility transformers ensure that electricity flows safely and reliably from generation points to end users, supporting modern life and infrastructure. Proper installation, maintenance, and handling are essential to maximize their efficiency, reliability, and lifespan.

Pole-mounted transformers are among the most visible elements of the electrical distribution system. A power pole transformer is typically mounted several feet above ground to maintain clearance and reduce risk to the public.

These transformers are commonly used in:

A telephone pole transformer may serve a single customer or multiple properties, depending on system design. Pole-mounted installations are cost-effective and allow easy access for utility crews performing maintenance or replacement.

While not mounted on poles, pad-mounted transformers are another important type of utility transformer. These units are installed at ground level and are commonly used in areas with underground power lines, such as newer residential developments or commercial campuses.

Pad-mounted transformers are enclosed in locked cabinets and placed on concrete pads. They offer a cleaner visual appearance and reduce overhead infrastructure, but they require careful placement and secure handling during installation.

Regardless of type, all transformers require careful handling during transport and staging. Utility transformer transport involves moving heavy, sensitive equipment that can be damaged by improper lifting, impact, or exposure to the elements.

During transport, transformers must be:

Damage sustained during transport may not be immediately visible but can affect long-term performance. This makes proper handling solutions a critical part of transformer management.

Selecting the correct transformer type depends on several factors:

A residential electric transformer may be sufficient for homes, while larger facilities require different configurations or multiple units. Understanding these distinctions helps utilities and contractors design systems that are both efficient and reliable.

For a deeper overview of transformer systems, configurations, and applications, explore Understanding Utility and Power Pole Transformers. This resource expands on how transformers function within the grid and why proper handling and protection are essential at every stage.

Transformers represent a long-term investment in electrical infrastructure. From manufacturing to installation, each step affects performance and lifespan. Using appropriate handling and protection solutions helps reduce risk, improve safety, and maintain system reliability.

ABG Bag supports professionals working with transformer equipment by providing solutions designed for real-world utility and construction environments. Our focus is on helping teams manage equipment safely and efficiently, whether they are installing a new system or maintaining existing infrastructure.

Residential neighborhoods, commercial areas, and industrial facilities all rely on different transformer types to meet their electrical needs. From a polemount transformer supplying a single home to larger utility systems supporting entire communities, each transformer plays a vital role in keeping power flowing.

Understanding the differences between transformer types allows for better planning, safer operations, and more reliable service for end users. Knowing the types of residential and utility transformers is an important part of managing electrical infrastructure effectively. Whether you’re planning a new installation, coordinating utility transformer transport, or preparing for maintenance or upgrades, having the right information and support makes a difference.

Call 800-758-8079 today or contact ABGBAG by submitting an online form to secure professional, dependable transformer containment solutions and protect your team, equipment, and environment.

For inquiries about our products, order status, or any other information related to ABG Bag Inc., send us a message, and we will respond soon.

Sales & Customer Care

Product Questions

Adding {{itemName}} to cart

Added {{itemName}} to cart